News Archive

Nathaniel Rutter, PhD student in radiological health sciences

Drilling rigs used to drill 450 feet into the earth to access the ore body

Photo courtesy of Dr. Tom Johnson

CSU students posing in front of hydrochloric acid tanks used in fuel processing

Photo courtesy of Dr. Tom Johnson

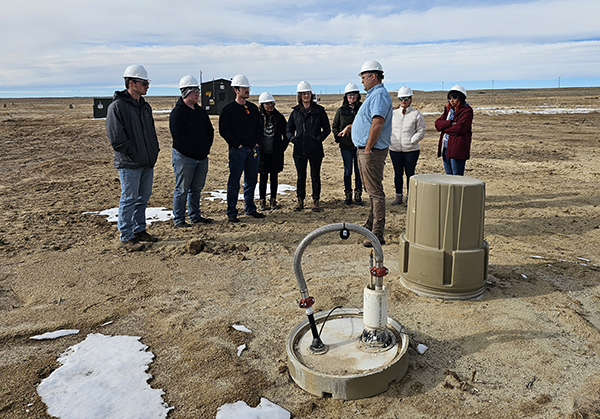

CSU students on a tour of the well field with Ryan Schierman standing next to an injection well

Photo courtesy of Dr. Tom Johnson

On Friday, 8 November 2024, students funded through a Mountains & Plains Education and Research Center (MAP ERC) grant toured the Lost Creek in-situ recovery (ISR) uranium mine north of Rawlins, Wyoming.

The day started with a 225-mile drive north from Colorado State University to the Great Basin and red desert of Wyoming. Surprisingly, driving into the compound did not reveal any large pits, excavators, or grandiose mining equipment. Instead, we were greeted by relatively undisturbed land, wild horses and antelopes, and small mounds of topsoil.

As we arrived at the uranium processing plant, Chris Pedersen (radiation safety officer), Oscar Paulson (special projects manager), and Ryan Schierman (vice president of regulatory affairs) directed the group up to their conference room, where we received a short introduction to in-situ uranium mining. They explained that the ISR process focuses on noninvasive mobilization of uranium minerals using oxygenated and carbonated (CO2) water (lixiviant). Wells approximately 137 meters deep are drilled in a grid-like pattern across the landscape to access the orebody underground. Injection wells are pumped with oxygenated/carbonated water solution that flows through the ore, effectively mobilizing the uranium by changing its oxidation state. The uranium-containing water (pregnant lixiviant) then flows to a recovery well located in the center of the grid. The recovery well pumps water up from the ground at a high flow rate, forcing the mineralized water solution to follow a calculated path. This process prevents any mobilized uranium solution from leaching into groundwater aquifers. The solution is then pumped into a well house then into the plant for processing.

As we learned, each step is highly controlled and scrutinized to prevent violations and loss of uranium. As soon as geologists assess the land to determine where to drill, the team is under strict rules and regulations, and their job does not end until the yellowcake is dried and safely packaged for shipping. Chris's job as the RSO is to ensure that the workers in the plant and well field are protected from radiation dose, as well as ensuring that uranium mining regulations are being followed. That includes routine testing of equipment and use of personnel monitoring equipment (dosimeters) to measure an individual's exposure to ionizing radiation. If doses are at a dangerous level, or PPE is not working sufficiently, or if contamination is detected in places that could present a hazard to worker health or safety, it's his job to assess and correct the plant's processes to protect workers and the environment.

In our tour of the plant, we got to shadow his daily duties, including monitoring of surfaces and air for contamination and learning how he is using shielding to reduce radiation dose rates in high-traffic areas of the facility. We also got to see how the uranium solution is processed through extraction and recovery columns, which represent a large area of the main warehouse.

Overall, the Lost Creek mine tour was highly educational and a very exciting experience to step out of the classroom to witness the first step in the nuclear energy infrastructure.